Features

- Times single or cumulative events from 1 µs to 999,999 hrs

- Transmits single event time or accumulated time of all events

- Timing resolution to 0.2 µs

- Timing from 0.2 µs to 999,999 hrs

- Selectable HH.MM.SS clock format or 6-digit H, M or S decimal format

- Inputs from NPN or PNP proximity switches, contact closures, digital logic, magnetic pickups down to 12 mV, or AC inputs up to 250 Vac

- Triggers on positive or negative pulse edges

- Digital span adjust from 0 to ±999,999, zero adjust from -999,999 to +999,999

- Front panel scalable: to ±999,999 for use with current shunts

- 1/8 DIN size with bright red or green 0.56" (14.2mm), high LED digits

- Transducer excitation output, 5, 10, 12, or 24 Vdc (isolated)

- Power 85-264 Vac / 90-300 Vdc or 10-48 Vdc / 12-32 Vac (isolated)

- Operating temperature from -40°C to 70°C (-40°F to 158°F)

- Wide choice of Plug-in-Play options:

- 2 or 4 relays, mechanical or solid state, for alarm or control (isolated)

- 1 or 2 Analog output, 4-20 mA, 0-20 mA, 0-10V, or -10V to +10V (isolated)

- Communications: Ethernet, WiFi, USB, RS232, RS485 (isolated)

- Extended DPM includes rate and total simultaneously, dynamic up-down counting, arithmetic functions

Certificates of Compliance

The Laureate™ 1/8 DIN Panel Meter, 6-digit digital stopwatch and timer

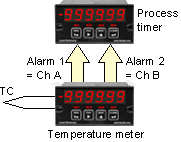

can record single or cumulative events ranging from 1 µs to 999,999 hours, with a timing resolution as precise as 0.2 µs. It offers selectable time display formats in HH:MM:SS or 6-digit H, M, or S decimal format, accommodating a variety of measurement needs. Compatible with inputs from NPN or PNP proximity switches, contact closures, digital logic, magnetic pickups as low as 12 mV, and AC inputs up to 250 Vac, it triggers on both positive and negative pulse edges. The device operates on a broad power range of 85-264 Vac / 90-300 Vdc or 10-48 Vdc / 12-32 Vac with (isolated) transducer excitation output. It functions reliably in temperatures from -40°C to 70°C. Additionally, it offers a wide range of options including 2 or 4 relays (mechanical or solid-state, (isolated)), 1 or 2 analog outputs (isolated), and various communication interfaces such as Ethernet, WiFi, USB, RS232, and RS485 (isolated).- A-A Stopwatch Mode. Time can be measured between a start pulse and a stop pulse, both on Channel A, from either the positive or negative edges.

- A-B Stopwatch Mode. Time can also be measured between a start pulse on Channel A (positive or negative edge) and a stop pulse on Channel B (positive or negative edge). This mode allows inputs from different sources. In addition, the A and B inputs can be tied together to start the stopwatch with one polarity and stop it with the other polarity.

- Rate Based on 1/Time Mode. Highly accurate rate can be displayed by taking the inverse of time. Extensive arithmetic capabilities allow display in engineering units, such as meter/sec. This mode requires use of an Extended counter.

Display. The event time (Item #1) may be displayed as a decimal number with six-digit resolution. The longest single-event timing interval is 999,999 hours. The highest resolution is 0.2 µs. The event time may also be displayed in HH.MM.SS clock format with 1 s resolution. The stopwatch display is updated during timing at a rate controlled by a gate time, up to 25/s. It is reset to zero when the next start pulse occurs. Accumulated time from multiple events (Item #2) is also tracked and may be displayed up to 999,999 hours.

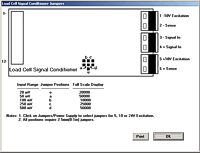

The FR dual-channel signal conditioner board accepts inputs from proximity switches with a PNP or NPN output, TTL or CMOS logic, magnetic pickups, contact closures, and other signals from 12 mV to 250 Vac. Jumper selections provide optimum operation for different sensor types and noise conditions. A built-in (isolated) 5, 10, 12, or 24 Vdc excitation supply can power proximity switches and other sensors, and eliminate the need for an external power supply.

Extended DPM includes rate and total simultaneously, dynamic up-down counting, arithmetic functions applicable to channels A & B (A+B, A-B, A/B, AxB, A/B-1), phase angle, power factor, duty cycle, batch control, custom curve linearization.

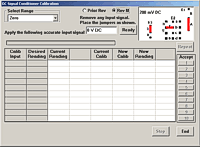

The Laureate Panel Meter is easily programmed with Laurel’s free Instrument Setup Software, downloadable from our website and compatible with Windows PCs, requiring a data interface board for setup.

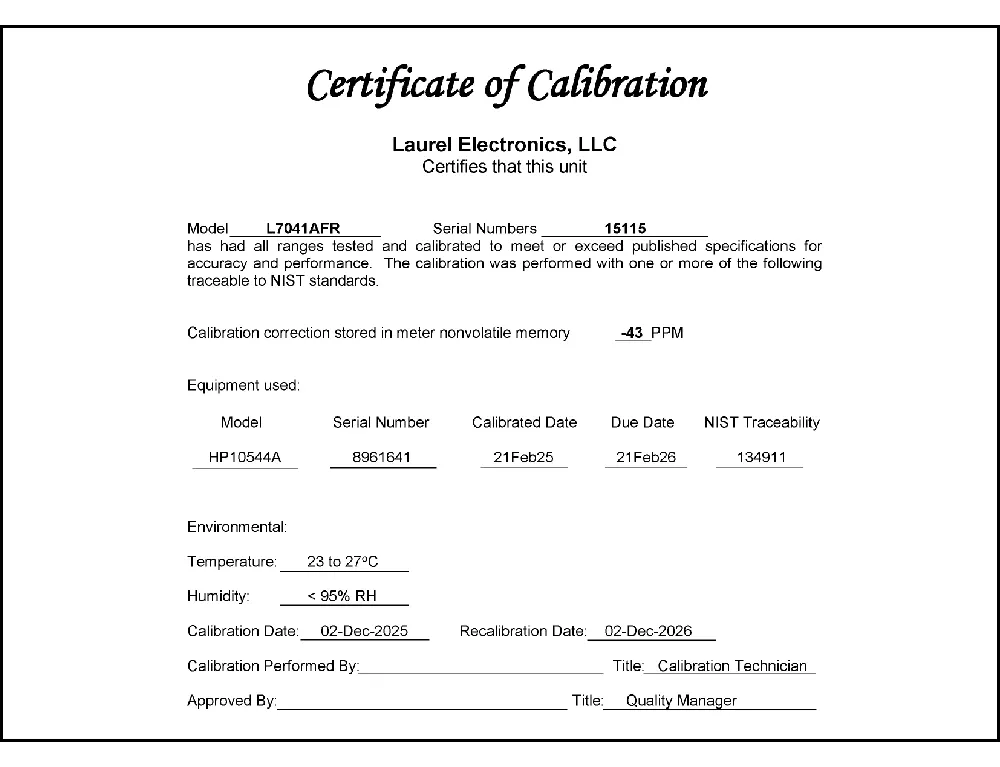

All signal conditioner board ranges are factory-calibrated, with calibration factors for each range securely stored in an onboard EEPROM. These factors can be scaled via software to accommodate external shunts, enabling field replacement of signal conditioner boards without necessitating recalibration of the associated panel meter. For optimal accuracy, factory recalibration is recommended annually. All Laurel Electronics instruments undergo factory calibration using the industry-leading Fluke calibrators, which are recalibrated yearly and certified traceable to national standards, ensuring the highest level of precision and reliability.

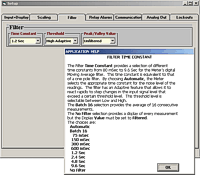

- An unfiltered selection provides true peak and valley readings and aids in control applications.

- A batch average filter selection averages each 16 conversions.

- An adaptive moving average filter selection provides a choice of 8 time constants from 80 ms to 9.6 seconds. When a significant change in signal level occurs, the filter adapts by briefly switching to the shortest time to follow the change, then reverts back to its selected time constant. An Auto setting selects the time constant selection based on signal noise.

Peak and valley values are automatically captured. These may be displayed via a front panel pushbutton command or control signal at the rear connector, or be transmitted as serial data.

Two rear panel control Inputs (CMOS/TTL levels, logic 0 = tied to digital ground, logic 1 = open) or dry contacts that can be set to control / activate 14 meter commands.

An (isolated) 5, 10, 12, or 24 Vdc excitation output is standard to power transducers or two-wire transmitters. Ratiometric operation, which automatically compensates for changes in the applied excitation, is jumper selectable for applications, such as bridges, where the signal to be measured is proportional to the excitation level.

| Display | |

|---|---|

| Readout | 5 LED digits, 7-segment, 14.2 mm (.56"), red or green. |

| Range | -999,999 to +999,999 |

| Indicators | Four LED lamps |

| Inputs | |

| Types | AC, pulses from NPN, PNP transistors, contact closures, magnetic pickups. |

| Grounding | Common ground for channels A & B |

| Minimum Signal | Nine ranges from (-12 to +12 mV) to (+1.25 to +2.1V). |

| Maximum Signal | 250 Vac |

| Noise Filter | 1 MHz, 30 kHz, 250 Hz (selectable) |

| Contact Debounce | 0, 3, 50 ms (selectable) |

| Recalibration: All ranges are calibrated at the factory. Recalibration is recommended every 12 months. | |

| Stopwatch Mode | |

| Timing Modes: | |

| With Ch A only | + to + edge, or - to - edge. |

| With Ch A tied to Ch B | + to - edge, or - to + edge. |

| With Ch A and Ch B | + edge of A to + edge of B, + edge of A to - edge of B, |

| - edge to A to - edge of B, - edge of A to - edge of B | |

| Timing Interval | 1 µs to 999,999 hrs |

| Timing Resolution | 0.2 µs to 1 hr |

| Selectable Decimal Time | 999999 H, M or S format with decimal point |

| Selectable Clock Time | HH.MM.SS format |

| Output & Display Update | 0 ms + programmable from 10 ms to 199.99 s |

| Accuracy | |

| Time Base | Crystal calibrated to ±2 ppm |

| Span Tempco | ±1 ppm/°C (typ) |

| Long-term Drift | ±5 ppm/year |

| Power Supply Boards (one required) | |

| Voltage, standard | 85-264 Vac or 90-300 Vdc |

| Voltage, optional | 12-32 Vac or 10-48 Vdc |

| Frequency | DC or 47-63 Hz |

| Power Isolation | 250V rms working, 2.3 kV rms per 1 min test |

| Excitation Output (standard) | |

| 5 Vdc | 5 Vdc ± 5%, 100 mA (jumper selectable) |

| 10 Vdc | 10 Vdc ± 5%, 120 mA (jumper selectable) |

| 12 Vdc | 12 Vdc ± 5%, 100 mA (jumper selectable) |

| 24 Vdc | 24 Vdc ± 5%, 50 mA (jumper selectable) |

| Output Isolation | 50 Vdc from signal ground |

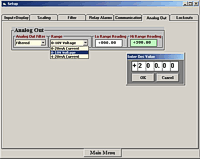

| Analog Output Boards (one optional) | |

| Output levels | 4-20 mA, 0-20 mA, 0-10V, -10 to +10V (single-output option) |

| 4-20 mA, 0-20 mA, 0-10V (dual-output option) | |

| Current compliance | 2 mA at 10V ( > 5 kΩ load) |

| Voltage compliance | 12V at 20 mA (< 600 Ω load) |

| Scaling | Zero and full scale adjustable from -99999 to +99999 |

| Resolution | 16 bits (0.0015% of full scale) |

| Isolation | 250V rms working, 2.3 kV rms per 1 min test |

| (dual analog outputs share the same ground) | |

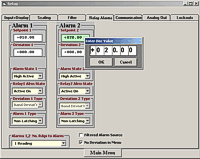

| Relay Output Boards (one optional) | |

| Dual magnetic relays | 2 Form C, 10A max, 440Vac or 125Vdc max, 2500VA or 300W |

| Quad magnetic relays | 4 Form A (NO), 10A max, 440Vac or 125Vdc max, 2500VA or 300W |

| Dual solid state relays | 2 Form A (NO), AC or DC, 0V - 400V, 120Ma, 35Ohms (max at On-State) |

| Quad solid state relays | 4 Form A (NO), AC or DC, 0V - 400V, 120Ma, 35Ohms (max at On-State) |

| Relay commons | Isolated commons for dual relays or each pair of quad relays |

| Relay isolation | 250V rms working, 2.3 kV rms per 1 minute test |

| Relay latching modes | Latching or non-latching |

| Relay active modes | Active on or off, active high or low |

| Hysteresis modes | QA passband mode, split hysteresis, span hysteresis |

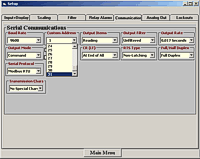

| Communication Boards (one optional) | |

| Board selections | RS232, RS485 with dual RJ11 connectors, RS485 with dual RJ45 connectors, USB, Ethernet, USB-to-RS485 gateway, Ethernet-to-RS485 gateway, WiFi with built-in antenna plus USB & RS485, WiFi with external antenna plus USB & RS485 |

| Protocols | Modbus RTU, Modbus ASCII, Modbus TCP (Ethernet), Laurel ASCII |

| Data rates | 300 to 19200 baud |

| Isolation | 250V rms working, 2.3 kV rms per 1 min test |

| Environmental | |

| Operating temperature | -40°C to 70°C (-40°F to 158°F) |

| Storage temperature. | -40°C to 85°C (-40°F to 185°F) |

| Relative humidity | 95% at 40°C, non-condensing |

| Protection | NEMA-4X (IP-65) when panel mounted |

| Electrical Connections | |

|

|

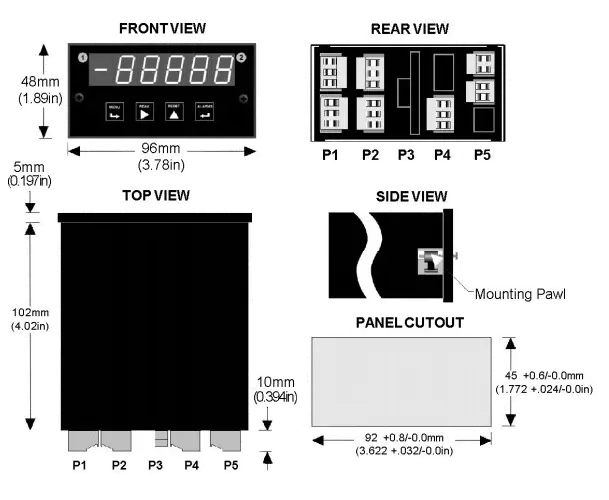

| Mechanical | |

| Enclosure | 1/8 DIN, high impact plastic, UL 94V-0, color: black |

| Mounting | 1/8 DIN panel cutout required: 3.622" x 1.772" (92 mm x 45 mm). |

| Dimensions | 4.68" x 2.45" x 5.64" (119 mm x 62 mm x 143 mm) (W x H x D) |

| Maximum panel thickness | 4.5 mm (0.18") |

| Tightening Torque - Connectors | Screw terminal connectors: 5 lb-in (0.56 Nm) |

| Tightening Torque - Pawls | Digital Panel Meter Case Pawls: 5 lb-in (0.56 Nm) |

| Weight of base meter | 210 g (7.4 oz) typical (DPM, counter, timer, 6-digit remote display) |

| Weight of option boards | 30 g (1.0 oz) typical per board (analog output, relay output, communications) |

| General | |

| Programming Methods | Four front panel buttons or via Laurel's free Instrument Setup Software, which runs on a PC under MS Windows. |

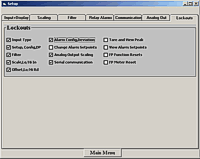

| Security | Lockout options include using the front panel buttons, the free Instrument Setup Software, or a hardware jumper. |

| Warranty | 3 years parts & labor |

| Recalibration: All ranges are calibrated at the factory. Recalibration is recommended every 12 months. | |

Free Instrument Setup Software for Series 2 Laureates

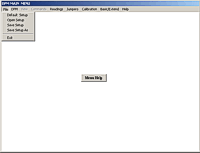

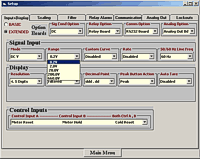

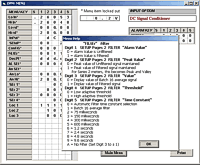

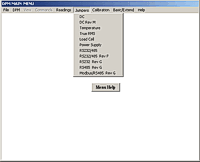

Free Downloadable Windows-based Instrument Setup (IS) software (Data Interface Board Required) for use with our programmable Digital Panel Meters, Scale Meters, Counters, Timers, Remote Displays, and Transmitters, are an easy method to set up Laureate 1/8 DIN digital panel meters, counters, timers, remote displays, and DIN-rail transmitters, as explained in the Instrument Setup Software Manual. Laureate 1/8 DIN instruments can also be set up from the front panel, as explained in their respective Owners Manuals. Instrument Setup software is of benefit whether or not the PC is connected to the instrument.

- When the PC is connected to the instrument, Instrument Setup software can retrieve the setup file from the instrument or open a default setup file or previously saved setup file from disk View Setup, then provides graphical user interface (GUI) screens with pull-down menus applicable to input, display, scaling, filtering, alarms, communications, analog output, and front panel lockouts. Fields that are not applicable to the instrument as configured are either left out or grayed out. Clicking on any item will bring up a detailed Help screen for that item. After editing, the setup file can be downloaded, uploaded to the instrument, or saved to a disk. The same setup file can then be downloaded into multiple instruments.

- When the PC is not connected to the instrument, the above GUI screens can be used to set up a virtual instrument. The setup file can then be saved to disk. Switching toView Menu then brings up a screen with the required front panel programming steps. This view can be printed out for use at the instrument site and to serve as a hard copy record.

Download Free Instrument Setup Software

Installation

Set User Account Control (UAC) of MS Windows to "Never notifiy me" so that Instrument Setup Software can create directories. The UAC change screen can be reached as follows:

- Under Windows 7, click on the Windows Start button in the lower left of the desktop and enter "UAC" in the search field.

- Under Windows 8, navigate to Control Panel, then to the "User Accounts and Family Safety" section, and click on "Change User Account Control Settings."

- Under Windows 10, click on the Windows Start button in the lower left of the desktop, then on "Settings", and enter "UAC" in the search field.

- Reboot your computer for the changed UAC setting to take effect.

RJ11-to-DB9 cable with rear view of DB9 connector to PC

RS232 cable, meter to PC, P/N CBL01

Laureate 1/8 DIN Laureate instruments must be equipped with a serial communications board and be connected to the computer via a serial communications cable. The connection can be via RS232, RS485, USB or Ethernet. Following setup, the serial communications board may be removed from the instrument if desired. The wiring of the RS232 cable is illustrated above with end views of the two connectors.

Laureate LT Series transmitters come standard with a 3-wire serial interface, which can be jumpered for RS232 or RS485.

Laureate LTE Series transmitters come standard with an Ethernet interface.

Meter Setup Screens

Click on any of the reduced screens below for a full-size screen view, then click on the Back button of your browser to return to this page. The screens examples below are for a fully-loaded Series 2 Digital Panel Meter (DPM), which is connected to the PC via RS232. If the meter is a Series 1 meter (pre-2007), this is sensed by the software, and somewhat different screens are brought up. Please see Series 1 setup screens.

Meter Setup Utilities

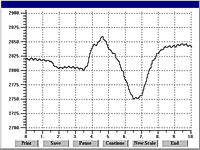

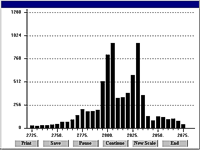

From the Main Menu, click on Readings if your PC is connected to the meter. A pull-down menu then offers three choices: List, Plot and Graph.

- List presents the latest readings in a 20-row by 10-column table. Press Pause at any time to freeze the display. This is one method to capture peak readings.

- Plot generates a plot of readings vs. time in seconds. It effectively turns the DPM-PC combination into a printing digital oscilloscope.

- Graph generates a histogram where the horizontal axis is the reading and the vertical axis is the number of occurrences of readings. The display continually resizes itself as the number of readings increases.

Laureate™ 1/8 DIN Case For Laureate Digital Panel Meters, Counters, Timers & Remote Displays

Key Features

- Meets 1/8 DIN Standard.

- Installs from front of panel.

- Short depth behind the panel: only 4" (102 mm) plus connectors.

- Understated 0.157" (4 mm) thick bezel.

- Meets NEMA 4X (IP-65) for high-pressure wawshdon when panel mounted.

- Screw clamps connectors meet VDE / IEC / UL / CSA safety standards.

- Rugged GE Lexan® housing material.

- Safety certified per EN 61010-1.

Dimensions

Maximum panel thickness: 4.5 mm (0.18")

Weight of base meter: 210 g (7.4 oz) typical (DPM, counter, timer, 6-digit remote display)

Weight of option boards: 30 g (1.0 oz) typical per board (analog output, relay output, communications)

Tightening Torque - Connectors: Screw terminal connectors: 5 lb-in (0.56 Nm)

Tightening Torque - Pawls: Digital Panel Meter Case Pawls: 5 lb-in (0.56 Nm)

Dimensioned CAD assembly drawings in EPRT, STEP, x_t. dwg, pdf file formats: Laureate-meter-case.zip (zipping prevents browser from opening CAD files as text files).

Panel Mounting

Slide the meter into a 45 x 92 mm 1/8 DIN panel cutout. Ensure that the provided gasket is in place between the front of the panel and the back of the meter bezel.

The meter is secured by two pawls, each held by a screw, as illustrated. Turning each screw counterclockwise extends the pawl outward from the case and behind the panel. Turning each screw clockwise further tightens it against the panel to secure the meter.

Slide the meter into a 45 x 92 mm 1/8 DIN panel cutout. Ensure that the provided gasket is in place between the front of the panel and the back of the meter bezel.

The meter is secured by two pawls, each held by a screw, as illustrated. Turning each screw counterclockwise extends the pawl outward from the case and behind the panel. Turning each screw clockwise further tightens it against the panel to secure the meter.

Turning each screw counterclockwise loosens the pawl and retracts it into its well. This position allows installed meter to be removed from their panel, or new meters to be installed in a panel. Do not remove the screws from their pawls. Doing so would cause the screw and pawl to fall off and likely get lost. Do not overtighten so as not to damage the plastic parts.

| Stopwatch Mode | |

|---|---|

|

The stopwatch mode is used to time single events to one microsecond resolution between start and stop pulses on the same channel. The width of a single waveshape can be measured by tying the A and B channels together. |

| Timing Process Dynamics | |

|

The start and stop pulses used for timing can be generated by the dual relay board in a Laureate analog panel meter or digital counter. For instance, the start and stop pulse edges can be created as temperature passes two alarm setpoints, or as temperature cycles in a hysteresis control mode. |

| Rate Based on 1 / Time | |

|

The Extended stopwatch meter can be programmed to display highly accurate rate or speed based on time. For example photodetectors on Channels A and B can provide timing pulses as a fast-moving object breaks two light beams, and the meter can then display speed in engineering units such as ft/sec or m/sec. The display will be held until reset by an external control input. |

| Replacing an Oscilloscope with a Laureate Meter | |

|

An oscilloscope is great for viewing and timing pulses in a lab. However, in fixed installations where digital timing accuracy and control outputs are required, a low-cost Laureate time interval meter will be the instrument of choice. Resolution to 0.2 µs is feasible. |

| Instrumenting a Pulsed Laser System | |

|

|

| Some of the many possibilities in instrumenting a pulsed laser system with Laureate dual-channel counters: elapsed time, number of pulses, pulse width, pulse separation, duty cycle, and pulse rep rate. | |

CAL-Digital

Certificate of Calibration

$65.00DLS-XLOG2

XLog2 Data logging Software

$495.00IPC

Splashproof Cover

$48.00CON01

CON01 Connector

$75.00CBL01

RS232 Cable for Meters

$35.00CBL02

USB-to-RS232 Adapter Cable

$47.00CBL04

RS232 Cable for LT Transmitters

$47.00CBL05

USB Data Cable for Meters

$47.00CBL06

USB-to-RS485 Adapter Cable

$47.00CBL07

USB Programming & Data Cable

$47.00CBL08

RS485 Splitter Cable

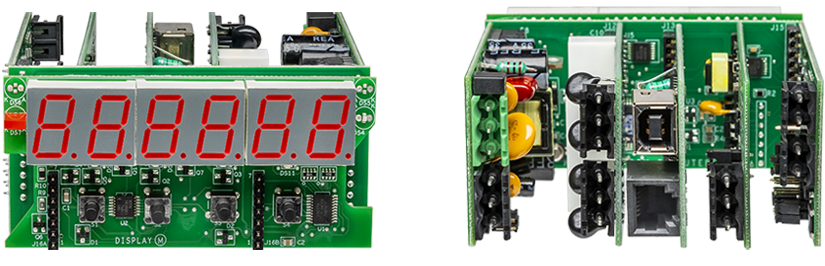

$33.00Modular Design for Maximum Flexibility at Minimum Cost

All boards are isolated from meter and power grounds. Optional Plug-in-Play boards for communications and control include Ethernet, WiFi, serial communication boards, dual or quad relay boards, and an analog output board. Laureates may be powered from 85-264 Vac or optionally from 12-32 Vac or 10-48 Vdc. The display is available with bright red or green 0.56" (14.2mm) high LED digits. The 1/8 DIN case meets NEMA 4X (IP65) specifications from the front when panel mounted. Any setup functions and front panel keys can be locked out for simplified usage and security. A built-in 5, 10, 12, or 24 Vdc excitation supply can power transducers, eliminating the need for an external power supply. All power and signal connections are via UL / VDE / CSA rated screw clamp plugs.

The Laureate™ Series features modular design with up to 7 isolated plug-in boards, applicable to all Laureate 1/8 DIN Panel Meter.

Modular Hardware

The design of the Laureate™ Series is modular for maximum flexibility at minimum cost. All boards are isolated from meter and power grounds. The base configuration for a panel meter or counter consists of a main module (with computer and plug-in display boards), a power supply board, and a signal conditioner board. Optional plug-in-play boards include an isolated setpoint controller board, an isolated analog output board, and an isolated digital interface board. Modular design and a choice of plug-in options allow the Laureate to be customized for a broad range of applications from simple monitoring to control and computer interface. There can be up to five plug-in boards in a 1/8 DIN Laureate.

Connecting Laureate Panel Meter to a Local Area Network (LAN)

Up to 30 Laureate Panel Meter and/or LT Transmitters can be configured for RS485 and daisy-chained to an LT Transmitter using Laurel’s High Speed Ethernet-to-RS485 converter board for seamless LAN integration. Alternatively, Laurel LTE series Ethernet transmitters can connect directly to a LAN via an Ethernet cable. Setup for both configurations is streamlined using Laurel’s free Instrument Setup Software, which simplifies node discovery and transmitter configuration.

Flexible Communication Options for Panel Meter

The Laureate Panel Meter can be equipped with Laurel communication boards to support various interfaces and protocols. These include serial interfaces with ASCII or Modbus RTU protocols, and Ethernet interfaces with web access, ASCII, or Modbus TCP/IP protocols, ensuring versatile connectivity for your commercial applications.

Understanding the 1/8 DIN Panel Meter for a 6-Digit Digital Stopwatch and Timer

Introduction

In industrial, laboratory, and commercial environments, precise timing is essential for ensuring operational efficiency, maintaining quality control, upholding safety standards, and meeting regulatory compliance requirements. A 1/8 DIN Panel Meter integrated with a 6-digit digital stopwatch and timer provides a high-precision, compact solution for accurate time-based measurements. This advanced device combines the reliability of a standardized panel meter with the versatility of a high-resolution timing instrument, making it a critical tool for applications requiring meticulous time tracking, process synchronization, and performance monitoring. This section delves into the functionality, features, benefits, and extensive applications of this specialized Panel Meter.

What is a 1/8 DIN Panel Meter?

A 1/8 DIN Panel Meter is a compact electronic instrument designed to display numerical data in a wide range of settings, including manufacturing plants, research laboratories, process control systems, and testing facilities. The "1/8 DIN" designation refers to its standardized size, defined by the Deutsches Institut für Normung (DIN), with front panel dimensions of approximately 96mm x 48mm (3.78" x 1.89"). This compact footprint allows for seamless integration into control panels, dashboards, or instrumentation setups, even in space-constrained environments where multiple parameters must be monitored simultaneously.

The Panel Meter is capable of processing and displaying various types of input signals, such as voltage, current, temperature, or time, using a high-visibility digital LED or LCD display. In the case of a stopwatch and timer, the Panel Meter serves as a precise timing interface, providing clear, high-resolution readouts that enhance operational monitoring and control across diverse applications.

What is a 6-Digit Digital Stopwatch and Timer?

A 6-digit digital stopwatch and timer is a high-precision timing instrument designed to measure and display time intervals with exceptional detail and accuracy. The six-digit display enables fine-grained time representation, typically covering formats such as HH:MM:SS (hours:minutes:seconds), MM:SS.ss (minutes:seconds.hundredths), or SSS.sss (total seconds with milliseconds). This level of resolution is ideal for applications requiring exact timing, such as monitoring production cycles, tracking experimental durations, synchronizing automated processes, or measuring performance metrics.

The stopwatch function measures elapsed time from a starting point with precision down to 0.01 seconds (10 milliseconds) or 0.001 seconds (1 millisecond) depending on the model, while the timer function can count up to a target value (count-up timer) or count down from a preset value (count-down timer), offering flexibility for a wide range of timing requirements. Advanced models support split timing (lap time), cumulative timing, and interval timing capabilities. This dual functionality makes the Panel Meter adaptable to both continuous and event-based timing needs in industrial, scientific, and commercial settings.

How Does a 1/8 DIN Panel Meter with Stopwatch and Timer Work?

The integration of a 1/8 DIN Panel Meter with a 6-digit digital stopwatch and timer creates a powerful and user-friendly timing solution. The Panel Meter serves as the primary interface for displaying and controlling time data, leveraging internal or external signals to achieve high accuracy. The operation involves the following key steps:

-

Time Signal Processing: The Panel Meter processes timing signals from an internal high-precision crystal oscillator (typically 10 ppm accuracy or better) or external triggers, such as pushbuttons, proximity sensors, photoelectric sensors, limit switches, or programmable logic controller (PLC) signals, to initiate, pause, resume, or reset the stopwatch or timer functions with microsecond-level response time.

-

Digital Conversion and Time Keeping: Time data is converted into a digital format using a real-time clock (RTC) or counter circuit and displayed on the 6-digit screen with high resolution, ensuring precise and readable outputs for operators or control systems. The Panel Meter maintains accurate time measurement even during power interruptions through battery backup or non-volatile memory retention.

-

Programmable Controls: Users can configure settings such as time units (e.g., hours, minutes, seconds, milliseconds, or custom formats), count direction (up, down, or bidirectional), preset values, timing modes (stopwatch, timer, real-time clock), alarm thresholds, and auto-repeat functions, tailoring the Panel Meter to specific application requirements through front-panel programming or PC configuration software.

-

Output and Integration: The Panel Meter supports outputs like programmable alarms (high, low, window, deviation), relay outputs (SPDT, typically 5A) for controlling external devices, 4-20mA analog retransmission proportional to elapsed time, pulse outputs for downstream counters, or communication interfaces (RS-232, RS-485, Modbus RTU/TCP, Ethernet) to trigger actions at specific time intervals or integrate with broader control systems, such as PLCs, distributed control systems (DCS), SCADA platforms, or building management systems (BMS).

-

Data Logging and Reporting: Advanced Panel Meter models include internal memory for storing time stamps, event logs, and timing histories for quality assurance documentation, process validation, and performance analysis.

Technical Specifications

While specific features vary by model, a typical 1/8 DIN Panel Meter with a 6-digit digital stopwatch and timer includes the following specifications:

- Display: 6-digit high-brightness LED (red, green, amber) or backlit LCD display with 0.56" or 0.8" character height, customizable time units, decimal points, and display modes.

- Timing Resolution: 0.01 seconds (10ms), 0.001 seconds (1ms), or 0.0001 seconds (0.1ms) depending on model and mode.

- Timing Range: Up to 999,999 seconds (over 277 hours) or customizable hour:minute:second format up to 99:59:59.

- Timing Accuracy: ±10 ppm (±0.001%) or ±50 ppm typical, equivalent to ±0.86 seconds per day.

- Input Types: Supports external triggers including NPN, PNP, TTL, voltage pulses (5-30VDC), dry contact inputs, and manual pushbutton controls for start/stop/reset/lap functions.

- Timing Modes: Stopwatch (count-up), count-down timer, interval timer, real-time clock, split/lap timing, totalizing timer.

- Preset Values: 1-4 programmable preset times with independent alarm outputs.

- Relay Outputs: 2-4 SPDT relays (5A @ 250VAC typical) for time-based control.

- Analog Output: 4-20mA or 0-10V proportional to elapsed or remaining time (optional).

- Communication: RS-232, RS-485, Modbus RTU, Modbus TCP/IP, Ethernet/IP for remote monitoring and control.

- Power Supply: 12-24V DC or 85-265V AC universal input, accommodating various industrial power systems.

- Battery Backup: Lithium battery backup for maintaining time during power loss (optional).

- Environmental Rating: IP65 or IP67 for front-panel protection against dust, moisture, and washdown conditions; operating temperature -10°C to 60°C.

- Memory: Non-volatile memory retaining presets, configurations, and timing data through power cycles.

Key Features and Benefits

The 1/8 DIN Panel Meter with a 6-digit digital stopwatch and timer offers a robust set of features that enhance its utility in time-critical applications:

-

Compact Design: The standardized 1/8 DIN size ensures easy installation in space-constrained control panels, instrument clusters, or portable test equipment, maximizing efficiency without compromising functionality or readability.

-

High Precision: The 6-digit display with sub-second resolution provides fine-grained timing down to milliseconds or hundredths of a second, with crystal-controlled accuracy of ±10-50 ppm, critical for precise timing applications, process validation, and quality assurance.

-

Versatility: Supports multiple timing modes (stopwatch, timer, totalizer, real-time clock), operates in count-up or count-down modes, and accommodates diverse industries and applications from manufacturing and automation to scientific research and sports timing.

-

Ease of Use: Features an intuitive digital interface with clear, high-visibility displays, front-panel pushbuttons or capacitive touch controls for starting, stopping, resetting, or configuring the stopwatch and timer, and user-friendly menu navigation accessible to operators with varying levels of expertise.

-

Customization: Offers programmable options for display formats (HH:MM:SS, MM:SS.ss, total seconds), time units, operational modes, alarm setpoints, auto-repeat cycles, and scaling factors, allowing users to tailor the Panel Meter to specific requirements and applications.

-

Robust Construction: Designed for industrial environments, with rugged ABS or polycarbonate enclosures, high IP ratings (IP65/IP67) for protection against dust, moisture, chemicals, and harsh conditions, EMI/RFI filtering for electrical noise immunity, and wide operating temperature ranges.

-

Integration Capabilities: Supports multiple output options, including relay contacts for direct device control, analog signals (4-20mA, 0-10V) for chart recorders or PLCs, pulse outputs for counters, and serial communication (RS-485, Modbus, Ethernet) for seamless integration with control systems, data acquisition systems, or remote monitoring platforms.

-

Advanced Timing Functions: Includes split/lap timing for tracking multiple intervals, interval timing for repetitive cycles, totalizing for cumulative time tracking, and multi-preset timers for sequential operations.

-

Alarm and Control: Programmable alarm outputs trigger at specific time values, enabling automated process control, safety interlocks, quality notifications, or production scheduling.

-

Data Retention: Non-volatile memory stores timing data, presets, and configurations through power cycles, while battery backup maintains timing during power interruptions, ensuring no loss of critical timing information.

Applications

The 1/8 DIN Panel Meter with a 6-digit digital stopwatch and timer is a versatile tool used in a wide range of applications requiring precise time tracking. Its high-resolution display and programmable functionality make it suitable for:

- Manufacturing Processes: Monitors production cycle durations, machine uptimes, assembly times, and process intervals to ensure consistency, optimize throughput, reduce bottlenecks, and maintain quality standards in assembly lines, machining operations, or injection molding.

- Testing and Quality Control: Tracks test durations for product performance evaluations, burn-in testing, life cycle testing, and accelerated aging tests, ensuring accurate and repeatable results in quality assurance processes and compliance with testing standards.

- Automation Systems: Synchronizes time-based operations in automated processes, such as coordinating robotic movements, controlling batch processing cycles, managing conveyor timing, or sequencing multiple operations with precise timing intervals.

- Research Laboratories: Measures precise time intervals for chemical reactions, biological incubations, physical tests, or material curing in fields like chemistry, physics, biology, or materials science, ensuring reliable data collection, reproducible experiments, and compliance with research protocols.

- Sports and Fitness Equipment: Tracks workout or training durations, rest intervals, exercise cycles, or competition times in fitness machines, timing systems, or athletic training facilities, providing accurate timing for user performance monitoring and coaching feedback.

- Process Control: Controls timed sequences in chemical processing, water treatment, pharmaceutical manufacturing, or food production to ensure proper reaction times, dosing durations, or treatment cycles.

- Medical Equipment: Times therapy sessions, sterilization cycles, equipment calibration, or diagnostic procedures in healthcare facilities to ensure patient safety and treatment efficacy.

Where Is a 1/8 DIN Panel Meter for a 6-Digit Digital Stopwatch and Timer Used?

The 1/8 DIN Panel Meter with a 6-digit digital stopwatch and timer is a critical instrument in industries and settings where timing accuracy directly impacts efficiency, quality, and safety. Its compact design, high precision, and robust integration capabilities make it indispensable across a variety of applications. Below is a detailed exploration of its primary use cases:

1. Manufacturing and Production Lines

In manufacturing, precise timing is essential for maintaining consistent production rates, ensuring product quality, and meeting throughput targets. The Panel Meter is used to:

- Monitor Cycle Times: Tracks the duration of each production step, injection molding cycle, assembly operation, or machining process, ensuring processes adhere to time targets, identifying bottlenecks, and optimizing overall throughput for maximum productivity.

- Control Machine Operations: Manages timed operations, such as activating or deactivating machinery, controlling dwell times, managing cure cycles, or sequencing multi-step processes at precise intervals, enhancing automation accuracy, efficiency, and product consistency.

- Quality Control: Times critical processes like curing, drying, coating, annealing, or heat treatment to prevent under-processing (weak products) or over-processing (material degradation), ensuring products meet stringent quality standards, specifications, and customer requirements.

- Shift Performance Tracking: Measures operational durations, downtime, changeover times, and production runs to analyze shift productivity, calculate OEE (Overall Equipment Effectiveness), identify opportunities for process improvements, and support lean manufacturing initiatives.

- Operator Pacing: Provides timing reference for manual assembly operations to maintain consistent work pace and meet takt time requirements.

2. Laboratory Testing and Calibration

In research and testing laboratories, accurate timing is vital for ensuring the reliability, repeatability, and validity of experimental results and equipment performance. The Panel Meter supports:

- Experiment Duration Tracking: Records precise time intervals for chemical reactions, polymerization processes, catalytic reactions, physical tests, biological incubations, cell cultures, or material aging, ensuring consistent experimental conditions, reproducible results, and compliance with research protocols and good laboratory practices (GLP).

- Instrument Calibration: Times calibration cycles for analytical instruments, testing equipment, or measurement devices, ensuring they meet required timing specifications, performance standards, and ISO 17025 accreditation requirements for calibration laboratories.

- Environmental Testing: Monitors exposure durations for stress tests, temperature cycling, humidity exposure, UV aging, corrosion testing, or vibration testing to evaluate material durability, product reliability, and performance under accelerated conditions.

- Timed Sampling: Controls sampling intervals in air quality monitoring, water testing, or process analysis to ensure representative samples and accurate analytical results.

3. Automation Systems

Automation systems in industries like manufacturing, pharmaceuticals, food processing, and chemical production rely on precise timing to ensure synchronized operations, process control, and product consistency. The Panel Meter is used to:

- Synchronize Processes: Coordinates timing across multiple system components, production zones, or parallel operations, preventing delays, misalignments, or collisions in automated production lines, robotic cells, or material handling systems.

- Control Batch Processing: Manages batch durations, mixing times, reaction periods, or rest intervals for processes like mixing, blending, filling, fermentation, or packaging, ensuring consistent output, recipe compliance, and regulatory adherence in pharmaceutical GMP or food HACCP systems.

- Sequence Control: Triggers sequential operations, step functions, or cascading processes at precise intervals, enhancing the efficiency and reliability of complex automated workflows, including multi-stage cleaning, coating, or assembly sequences.

- Interlock Timing: Implements safety delays, purge cycles, or lockout periods in automated systems to ensure safe equipment operation and prevent hazardous conditions.

4. Energy Management and Utilities

In energy and utility systems, timing plays a critical role in optimizing resource use, reducing demand charges, and ensuring operational efficiency. The Panel Meter is applied in:

- Load Duration Monitoring: Tracks the operational time of specific loads, such as pumps, compressors, chillers, HVAC systems, or industrial equipment, to optimize energy consumption, implement load shedding, reduce peak demand charges, and lower utility costs.

- Timed Operations Control: Manages scheduled processes in utilities, such as water treatment dosing cycles, filtration backwash timing, aeration periods, or gas distribution valve sequencing, ensuring efficiency, process optimization, and compliance with environmental regulations.

- Maintenance Scheduling: Monitors equipment runtime hours, operating cycles, or duty cycles to schedule preventive maintenance based on actual usage rather than calendar time, minimizing unexpected downtime, extending asset lifespan, and reducing maintenance costs.

- Demand Response: Times load curtailment periods during peak pricing to participate in utility demand response programs and reduce energy costs.

5. Transportation and Logistics

In transportation and logistics, precise timing enhances efficiency in goods movement, vehicle management, and warehouse operations. The Panel Meter supports:

- Transit Time Monitoring: Records travel durations, loading/unloading times, or dwell times for vehicles, automated guided vehicles (AGVs), or goods to ensure adherence to delivery schedules, optimize route planning, and improve customer service levels.

- Timed Dispatch Control: Manages vehicle dispatch intervals, release sequences, or staging times to prevent congestion, balance workload, and improve logistics flow in warehouses, distribution centers, or cross-dock facilities.

- Conveyor Timing: Tracks timing for conveyor operations, sortation systems, or accumulation zones, ensuring synchronized material handling, preventing collisions, and optimizing throughput in automated sorting, picking, or packaging systems.

- Cycle Time Analysis: Measures pick times, pack times, or order fulfillment cycles to identify process improvements and increase warehouse productivity.

6. Healthcare and Medical Equipment

In healthcare, accurate timing is critical for patient safety, treatment efficacy, and regulatory compliance. The Panel Meter is used in:

- Medical Procedure Timing: Controls durations for devices like infusion pumps, syringe pumps, ventilators, or dialysis machines, ensuring precise medication delivery rates, therapy administration, or treatment protocols for patient safety.

- Treatment Monitoring: Tracks treatment durations for procedures like radiation therapy, phototherapy, hyperbaric oxygen therapy, or physical therapy sessions, maintaining safety, dosage accuracy, and therapeutic effectiveness.

- Equipment Calibration: Times calibration cycles, quality control tests, or performance verification for medical devices, analytical instruments, or diagnostic equipment, ensuring they operate within specified parameters for accurate patient care and regulatory compliance.

- Sterilization Cycles: Controls and documents autoclave, ethylene oxide, or UV sterilization times to ensure complete sterilization and compliance with infection control standards.

7. Food and Beverage Industry

In food and beverage processing, timing is essential for ensuring product quality, safety, consistency, and regulatory compliance. The Panel Meter is applied in:

- Processing Time Control: Monitors durations for cooking, baking, pasteurization, sterilization, or retort processing to achieve consistent product quality, ensure food safety, eliminate pathogens, and comply with USDA, FDA, or HACCP food safety standards.

- Packaging Operations: Times filling, capping, sealing, or labeling processes to maintain efficiency, accuracy, and synchronization in high-speed packaging lines, reducing waste and ensuring proper package integrity.

- Fermentation Monitoring: Tracks fermentation durations, aging times, or maturation periods to ensure optimal flavor development, alcohol content, culture activity, and quality in products like beer, wine, yogurt, cheese, or bread.

- CIP/SIP Cycles: Controls clean-in-place and sterilize-in-place cycle times to ensure complete cleaning and sanitation while minimizing water and chemical usage.

8. Chemical Processing

Chemical plants use the Panel Meter to control reaction times, mixing durations, catalyst contact times, and batch sequences, ensuring proper chemical conversion, product quality, and safe operations in processes handling hazardous materials.

9. Textile and Printing

Textile mills and printing facilities employ the Panel Meter for dyeing cycle control, curing times, drying durations, and web speed synchronization to maintain color consistency, print registration, and production quality.

Conclusion

The 1/8 DIN Panel Meter integrated with a 6-digit digital stopwatch and timer is a versatile, high-precision tool that plays a pivotal role in time-critical applications across multiple industries. Its compact design, high-resolution display with millisecond precision, crystal-controlled accuracy, robust integration capabilities, and advanced timing functions make it indispensable for ensuring operational efficiency, quality control, process validation, safety compliance, and regulatory adherence in manufacturing, laboratories, automation, energy management, transportation, healthcare, food processing, and chemical production. The Panel Meter's ability to provide accurate timing, trigger automated actions, integrate with control systems, and document timing data makes it essential for modern industrial operations. As industries continue to advance and demand greater precision, traceability, and automation, the role of this Panel Meter will remain central to achieving reliable, accurate, and documented timing in complex processes.

Less Information.