Features

- Accepts low-level differential or single-ended 5V logic level signals from shaft encoders, linear encoders, incremental encoders or optical encoders

- 6-digit scalable display for position, length or rate

- Programmable for position, angle or rate

- Maximum pulse rates of 250 kpulses/sec at X1, 125 kpulses/sec at X2, 62.5 kpulses/sec at X4

- Display update rate up to 25/s

- Zero channel input

- Digital span adjust from 0 to ±999,999, zero adjust from -999,999 to +999,999

- Front panel scalable: to ±999,999 for use with current shunts

- 1/8 DIN size with bright red or green 0.56" (14.2mm), high LED digits

- Transducer excitation output, 5, 10, 12, or 24 Vdc (isolated)

- Power 85-264 Vac / 90-300 Vdc or 10-48 Vdc / 12-32 Vac (isolated)

- Operating temperature from -40°C to 70°C (-40°F to 158°F)

- Wide choice of Plug-in-Play options:

- 2 or 4 relays, mechanical or solid state, for alarm or control (isolated)

- 1 or 2 Analog output, 4-20 mA, 0-20 mA, 0-10V, or -10V to +10V (isolated)

- Communications: Ethernet, WiFi, USB, RS232, RS485 (isolated)

- Extended DPM includes set up for scaled position or rate, but not forsimultaneous position and rate

Certificates of Compliance

The Laureate™ 1/8 DIN Panel Meters for bidirectional position, length or angle measurement

with the Standard counter main board accepts the A & B quadrature signals from shaft encoders or linear encoders to provide a highly accurate, scaled display of position, length, or angle in engineering units, such as ft, cm or degrees. The A & B quadrature signals are 90° out of phase, and their phase relationship determines whether up counts (+) or down counts (-) are counted. The panel meters totalize the counts and then scales the total in software for display and control. A zero index signal, or Z signal, can be added as a third input to the A & B signals.Bidirectional Rate Measurement

The Laureate™ quadrature meter with the Extended counter main board can be set up for scaled position or rate, but not for simultaneous position and rate. For example, it can display the speed of a moving slab in ft/sec. The display and control output update rate for position or rate is normally set to a maximum of 25/sec, as determined by a user-programmable gate time.

Quadrature Meter Capabilities

- One, two or four quadrature transitions may be counted at a maximum combined rate of 250 kHz and be mathematically scaled for display in engineering units from -999,999 to +999,999. Maximum pulse rates are 250 kpulses/sec at X1, 125 kpulses/sec at X2, and 62.5 kpulses/sec at X4.

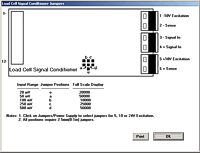

- Single-ended input signals up to 5V or balanced line driver signals up to 10V are accommodated by the quadrature signal conditioner board. Anti-jitter circuitry eliminates errors due to vibration of the encoder.

- An excitation output from the panel meters can be used to power the encoder, thus avoiding the need for an external powr supply. Jumper selectable levels are 100 mA at 5V or 120 mA at 10V.

- A zero index pulse, if available from the encoder, is interpreted by these panel meters as a zero reference for an integral number of revolutions of a rotary encoder, or as the home position of a linear encoder. It is used by these panel meters for initializing and correcting any cumulative pulse count errors. Special circuitry corrects for width of the zero index pulse.

- In the event of a power failure, the latest total can be stored in non-volatile memory and be used as the starting point for counting when power resumes. Power fail save or zero index capabilities are alternate setup choices for these panel meters.

Unidirectional Position and Rate

If the counts are only for one direction, for example for extrusions measured by an encoder wheel, only the encoder's "A" channel can be used and be output to an Extended Laureate totalizer. This model accommodates very high pulse rates up to 1 MHz, and unlike the quadrature meter, it can simultaneously track rate and total. It can also be programmed for batch control, which allows it to simultaneously track rate, batch (or current) total, and grand total or number of batches.

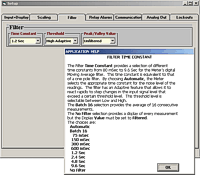

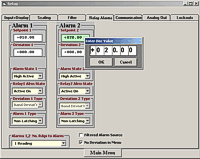

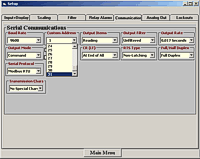

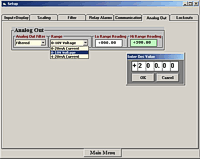

Laureate Digital Panel Meters are easily programmed with Laurel’s free Instrument Setup Software, downloadable from our website and compatible with Windows PCs, requiring a data interface board for setup.

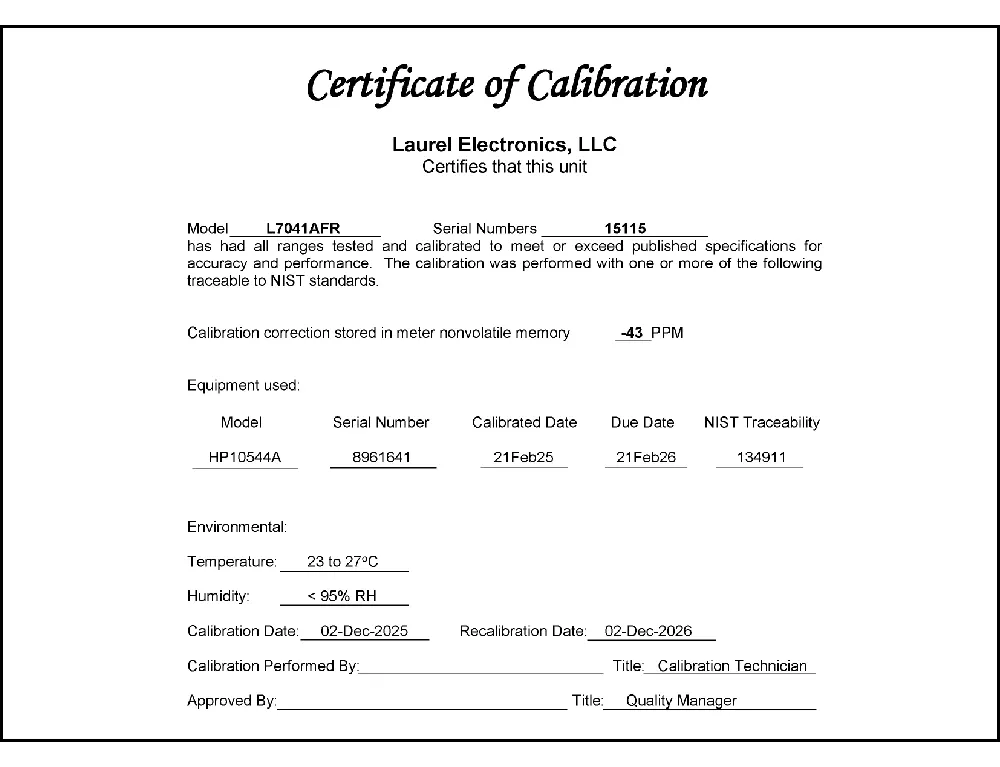

All signal conditioner board ranges are factory-calibrated, with calibration factors for each range securely stored in an onboard EEPROM. These factors can be scaled via software to accommodate external shunts, enabling field replacement of signal conditioner boards without necessitating recalibration of the associated digital panel meter. For optimal accuracy, factory recalibration is recommended annually. All Laurel Electronics instruments undergo factory calibration using the industry-leading Fluke calibrators, which are recalibrated yearly and certified traceable to national standards, ensuring the highest level of precision and reliability.

Digital signal filtering modes can be selected to ensure stable readings in electrically noisy environments.

- An unfiltered selection provides true peak and valley readings and aids in control applications.

- A batch average filter selection averages each 16 conversions.

- An adaptive moving average filter selection provides a choice of 8 time constants from 80 ms to 9.6 seconds. When a significant change in signal level occurs, the filter adapts by briefly switching to the shortest time to follow the change, then reverts back to its selected time constant. An Auto setting selects the time constant selection based on signal noise.

Peak and valley values are automatically captured. These may be displayed via a front panel pushbutton command or control signal at the rear connector, or be transmitted as serial data.

Two rear panel control Inputs (CMOS/TTL levels, logic 0 = tied to digital ground, logic 1 = open) or dry contacts that can be set to control / activate 14 meter commands.

An (isolated) 5, 10, 12, or 24 Vdc excitation output is standard to power transducers or two-wire transmitters. Ratiometric operation, which automatically compensates for changes in the applied excitation, is jumper selectable for applications, such as bridges, where the signal to be measured is proportional to the excitation level.

| Display | |

|---|---|

| Readout | 6 LED digits, 7-segment, 14.2 mm (.56"), red or green. |

| Display Range | -999,999 to +999,999, XXXXEX notation beyond 999,999 |

| Zero Adjust | -999,999 to +999,999 |

| Span Adjust | 0 to ±999,999 |

| Indicators | Four LED lamps |

| Inputs | |

| Types | Differential or single-ended quadrature |

| Transitions Monitored Inputs | X1, X2 or X4 (A,B and Z) |

| Max Pulse Rate | 250 kpulses/sec at X1, 125 kpulses/sec X2, 62.5 kpulses/sec at X4 |

| Position Error | No error contributed by meter |

| Differential High Threshold | +200 mV |

| Differential Low Threshold | -200 mV |

| Differential Limits | -11V to +14V |

| Single-ended High Voltage | 2.5V to 10V |

| Single-ended Low Voltage | -1V to +1V |

| Input Resistance, Typ. | 17 kOhm |

| Recalibration: All ranges are calibrated at the factory. Recalibration is recommended every 12 months. | |

| Quadrature Position Mode | |

| Zero Adjust | -999,999 to +999,999 |

| Span Adjust | 0 to ±999,999 |

| Quadrature Rate Mode | |

| Freq. Technique | Inverse period |

| Conversion Time | Gate time + 30 ms + 0-2 signal periods |

| Gate Time | Selectable 10 ms to 199.99 s |

| Time Before Zero Out | Selectable 10 ms to 199.99 s |

| Output & Display Update | Same as conversion time |

| Time Base Accuracy | Calibrated to ±2 ppm |

| Power Supply Boards (one required) | |

| Voltage, standard | 85-264 Vac or 90-300 Vdc |

| Voltage, optional | 12-32 Vac or 10-48 Vdc |

| Frequency | DC or 47-63 Hz |

| Power Consumption (typical, base meter) | 1.2W @ 120 Vac, 1.5W @ 240 Vac, 1.3W @ 10 Vdc, 1.4W @ 20 Vdc, 1.55W @ 30 Vdc, 1.8W @ 40 Vdc, 2.15W @ 48 Vdc |

| Power Isolation | 250V rms working, 2.3 kV rms per 1 min test |

| Excitation Output (standard) | |

| 5 Vdc | 5 Vdc ± 5%, 100 mA (jumper selectable) |

| 10 Vdc | 10 Vdc ± 5%, 120 mA (jumper selectable) |

| 12 Vdc | 12 Vdc ± 5%, 100 mA (jumper selectable) |

| 24 Vdc | 24 Vdc ± 5%, 50 mA (jumper selectable) |

| Output Isolation | 50 Vdc from signal ground |

| Analog Output Boards (one optional) | |

| Output levels | 4-20 mA, 0-20 mA, 0-10V, -10 to +10V (single-output option) |

| Current compliance | 2 mA at 10V ( > 5 kΩ load) |

| Voltage compliance | 12V at 20 mA (< 600 Ω load) |

| Scaling | Zero and full scale adjustable from -99999 to +99999 |

| Resolution | 16 bits (0.0015% of full scale) |

| Isolation | 250V rms working, 2.3 kV rms per 1 min test |

| (dual analog outputs share the same ground) | |

| Relay Output Boards (one optional) | |

| Dual magnetic relays | 2 Form C, 10A max, 440Vac or 125Vdc max, 2500VA or 300W |

| Quad magnetic relays | 4 Form A (NO), 10A max, 440Vac or 125Vdc max, 2500VA or 300W |

| Dual solid state relays | 2 Form A (NO), AC or DC, 0V - 400V, 120Ma, 35Ohms (max at On-State) |

| Quad solid state relays | 4 Form A (NO), AC or DC, 0V - 400V, 120Ma, 35Ohms (max at On-State) |

| Relay commons | Isolated commons for dual relays or each pair of quad relays |

| Relay isolation | 250V rms working, 2.3 kV rms per 1 minute test |

| Relay latching modes | Latching or non-latching |

| Relay active modes | Active on or off, active high or low |

| Hysteresis modes | QA passband mode, split hysteresis, span hysteresis |

| Communication Boards (one optional) | |

| Board selections | RS232, RS485 with dual RJ11 connectors, RS485 with dual RJ45 connectors, USB, Ethernet, USB-to-RS485 gateway, Ethernet-to-RS485 gateway, WiFi with built-in antenna plus USB & RS485, WiFi with external antenna plus USB & RS485 |

| Protocols | Laurel Custom ASCII (serial), Modbus RTU (serial), Modbus TCP (Ethernet or WiFi) |

| Digital addresses | 247 (Modbus), 31 (Laurel ASCII), |

| Isolation | 250V rms working, 2.3 kV rms per 1 min test |

| Environmental | |

| Operating temperature | -40°C to 70°C (-40°F to 158°F) |

| Storage temperature. | -40°C to 85°C (-40°F to 185°F) |

| Relative humidity | 95% at 40°C, non-condensing |

| Protection | NEMA-4X (IP-65) when panel mounted |

| Mechanical | |

| Enclosure | 1/8 DIN, high impact plastic, UL 94V-0, color: black |

| Mounting | 1/8 DIN panel cutout required: 3.622" x 1.772" (92 mm x 45 mm). |

| Dimensions | 4.68" x 2.45" x 5.64" (119 mm x 62 mm x 143 mm) (W x H x D) |

| Maximum panel thickness | 4.5 mm (0.18") |

| Tightening Torque - Connectors | Screw terminal connectors: 5 lb-in (0.56 Nm) |

| Tightening Torque - Pawls | Digital Panel Meter Case Pawls: 5 lb-in (0.56 Nm) |

| Weight of base meter | 210 g (7.4 oz) typical (DPM, counter, timer, 6-digit remote display) |

| Weight of option boards | 30 g (1.0 oz) typical per board (analog output, relay output, communications) |

| General | |

| Programming Methods | Four front panel buttons or via Laurel's free Instrument Setup Software, which runs on a PC under MS Windows. |

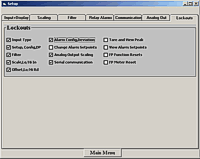

| Security | Lockout options include using the front panel buttons, the free Instrument Setup Software, or a hardware jumper. |

| Warranty | 3 years parts & labor |

| Recalibration: All ranges are calibrated at the factory. Recalibration is recommended every 12 months. | |

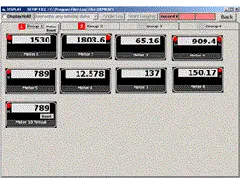

Free Instrument Setup Software for Series 2 Laureates

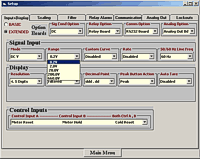

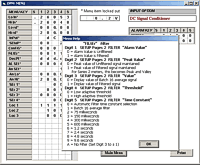

Free Downloadable Windows-based Instrument Setup (IS) software (Data Interface Board Required) for use with our programmable Digital Panel Meters, Scale Meters, Counters, Timers, Remote Displays, and Transmitters, are an easy method to set up Laureate 1/8 DIN digital panel meters, counters, timers, remote displays, and DIN-rail transmitters, as explained in the Instrument Setup Software Manual. Laureate 1/8 DIN instruments can also be set up from the front panel, as explained in their respective Owners Manuals. Instrument Setup software is of benefit whether or not the PC is connected to the instrument.

- When the PC is connected to the instrument, Instrument Setup software can retrieve the setup file from the instrument or open a default setup file or previously saved setup file from disk View Setup, then provides graphical user interface (GUI) screens with pull-down menus applicable to input, display, scaling, filtering, alarms, communications, analog output, and front panel lockouts. Fields that are not applicable to the instrument as configured are either left out or grayed out. Clicking on any item will bring up a detailed Help screen for that item. After editing, the setup file can be downloaded, uploaded to the instrument, or saved to a disk. The same setup file can then be downloaded into multiple instruments.

- When the PC is not connected to the instrument, the above GUI screens can be used to set up a virtual instrument. The setup file can then be saved to disk. Switching toView Menu then brings up a screen with the required front panel programming steps. This view can be printed out for use at the instrument site and to serve as a hard copy record.

Download Free Instrument Setup Software

Installation

Set User Account Control (UAC) of MS Windows to "Never notifiy me" so that Instrument Setup Software can create directories. The UAC change screen can be reached as follows:

- Under Windows 7, click on the Windows Start button in the lower left of the desktop and enter "UAC" in the search field.

- Under Windows 8, navigate to Control Panel, then to the "User Accounts and Family Safety" section, and click on "Change User Account Control Settings."

- Under Windows 10, click on the Windows Start button in the lower left of the desktop, then on "Settings", and enter "UAC" in the search field.

- Reboot your computer for the changed UAC setting to take effect.

RJ11-to-DB9 cable with rear view of DB9 connector to PC

RS232 cable, meter to PC, P/N CBL01

Laureate 1/8 DIN Laureate instruments must be equipped with a serial communications board and be connected to the computer via a serial communications cable. The connection can be via RS232, RS485, USB or Ethernet. Following setup, the serial communications board may be removed from the instrument if desired. The wiring of the RS232 cable is illustrated above with end views of the two connectors.

Laureate LT Series transmitters come standard with a 3-wire serial interface, which can be jumpered for RS232 or RS485.

Laureate LTE Series transmitters come standard with an Ethernet interface.

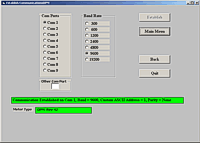

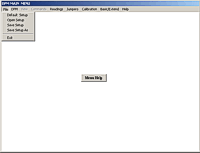

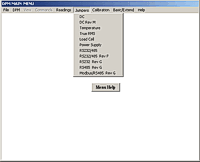

Meter Setup Screens

Click on any of the reduced screens below for a full-size screen view, then click on the Back button of your browser to return to this page. The screens examples below are for a fully-loaded Series 2 Digital Panel Meter (DPM), which is connected to the PC via RS232. If the meter is a Series 1 meter (pre-2007), this is sensed by the software, and somewhat different screens are brought up. Please see Series 1 setup screens.

Meter Setup Utilities

From the Main Menu, click on Readings if your PC is connected to the meter. A pull-down menu then offers three choices: List, Plot and Graph.

- List presents the latest readings in a 20-row by 10-column table. Press Pause at any time to freeze the display. This is one method to capture peak readings.

- Plot generates a plot of readings vs. time in seconds. It effectively turns the DPM-PC combination into a printing digital oscilloscope.

- Graph generates a histogram where the horizontal axis is the reading and the vertical axis is the number of occurrences of readings. The display continually resizes itself as the number of readings increases.

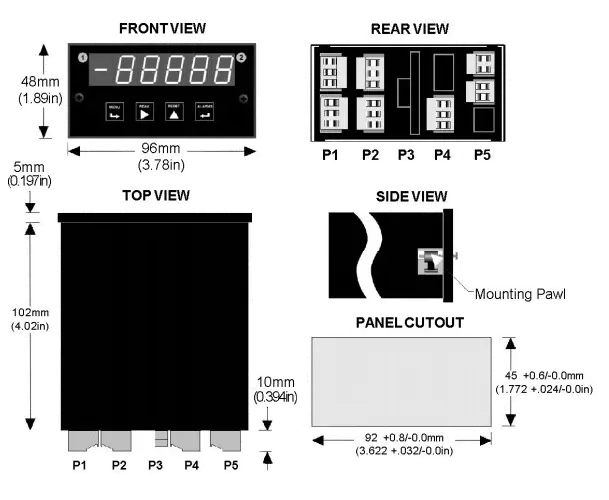

Laureate™ 1/8 DIN Case For Laureate Digital Panel Meters, Counters, Timers & Remote Displays

Key Features

- Meets 1/8 DIN Standard.

- Installs from front of panel.

- Short depth behind the panel: only 4" (102 mm) plus connectors.

- Understated 0.157" (4 mm) thick bezel.

- Meets NEMA 4X (IP-65) for high-pressure wawshdon when panel mounted.

- Screw clamps connectors meet VDE / IEC / UL / CSA safety standards.

- Rugged GE Lexan® housing material.

- Safety certified per EN 61010-1.

Dimensions

Maximum panel thickness: 4.5 mm (0.18")

Weight of base meter: 210 g (7.4 oz) typical (DPM, counter, timer, 6-digit remote display)

Weight of option boards: 30 g (1.0 oz) typical per board (analog output, relay output, communications)

Tightening Torque - Connectors: Screw terminal connectors: 5 lb-in (0.56 Nm)

Tightening Torque - Pawls: Digital Panel Meter Case Pawls: 5 lb-in (0.56 Nm)

Dimensioned CAD assembly drawings in EPRT, STEP, x_t. dwg, pdf file formats: Laureate-meter-case.zip (zipping prevents browser from opening CAD files as text files).

Panel Mounting

Slide the meter into a 45 x 92 mm 1/8 DIN panel cutout. Ensure that the provided gasket is in place between the front of the panel and the back of the meter bezel.

The meter is secured by two pawls, each held by a screw, as illustrated. Turning each screw counterclockwise extends the pawl outward from the case and behind the panel. Turning each screw clockwise further tightens it against the panel to secure the meter.

Slide the meter into a 45 x 92 mm 1/8 DIN panel cutout. Ensure that the provided gasket is in place between the front of the panel and the back of the meter bezel.

The meter is secured by two pawls, each held by a screw, as illustrated. Turning each screw counterclockwise extends the pawl outward from the case and behind the panel. Turning each screw clockwise further tightens it against the panel to secure the meter.

Turning each screw counterclockwise loosens the pawl and retracts it into its well. This position allows installed meter to be removed from their panel, or new meters to be installed in a panel. Do not remove the screws from their pawls. Doing so would cause the screw and pawl to fall off and likely get lost. Do not overtighten so as not to damage the plastic parts.

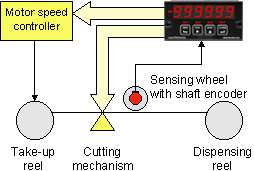

| Using Quadrature for Cutting to Length | |

|---|---|

|

Controlling the repetitive cutting of material to length is an excellent application of the Laureate quadrature meter. The quadrature encoder shares the shaft of a sensing wheel, whose rotation corresponds to lineal displacement of material. The meter compares the displacement reading against setpoint information, and then uses its dual relays to first slow down and then cut the material. |

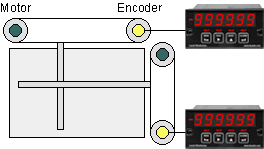

| Using Quadrature for X-Y Positioning | |

|

Accurate X-Y position or rate can be obtained from two shaft encoders, which convert linear position to quadrature signals as a shaft turns. In addition to serving as a display, each Laureate can use its optional dual relay setpoint capability for closed loop control. It can also transmit data via RS232, RS485, or a 4-20 mA analog signal. |

| Using Quadrature to Monitor a Drilling Operation | |

|

Quadrature can be used to track position and vertical drilling speed of the bit in an oil drilling operation. A shaft encoder is rotated by a cable that moves with the drilling shaft. In this application, the same encoder signal is applied to a Laureate quadrature meter for position, and to a second quadrature meter for rate. Both meters can be scaled to read out in appropriate engineering units, such as feet and inches per minute, and can be alarmed. A Laureate 6-digit remote display could be added to read out peak rate. |

CAL-Digital

Certificate of Calibration

$65.00DLS-XLOG2

XLog2 Data logging Software

$495.00IPC

Splashproof Cover

$48.00CON01

CON01 Connector

$75.00CBL01

RS232 Cable for Meters

$35.00CBL02

USB-to-RS232 Adapter Cable

$47.00CBL04

RS232 Cable for LT Transmitters

$47.00CBL05

USB Data Cable for Meters

$47.00CBL06

USB-to-RS485 Adapter Cable

$47.00CBL07

USB Programming & Data Cable

$47.00CBL08

RS485 Splitter Cable

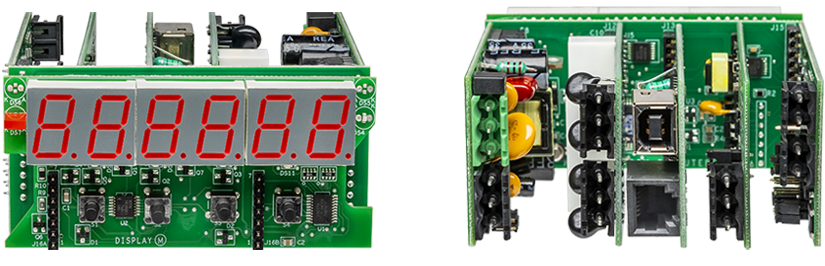

$33.00Modular Design for Maximum Flexibility at Minimum Cost

All boards are isolated from meter and power grounds. Optional Plug-in-Play boards for communications and control include Ethernet, WiFi, serial communication boards, dual or quad relay boards, and an analog output board. Laureates may be powered from 85-264 Vac or optionally from 12-32 Vac or 10-48 Vdc. The display is available with bright red or green 0.56" (14.2mm) high LED digits. The 1/8 DIN case meets NEMA 4X (IP65) specifications from the front when panel mounted. Any setup functions and front panel keys can be locked out for simplified usage and security. A built-in 5, 10, 12, or 24 Vdc excitation supply can power transducers, eliminating the need for an external power supply. All power and signal connections are via UL / VDE / CSA rated screw clamp plugs.

The Laureate™ Series features modular design with up to 7 isolated plug-in boards, applicable to all Laureate 1/8 DIN Panel Meters.

Modular Hardware

The design of the Laureate™ Series is modular for maximum flexibility at minimum cost. All boards are isolated from meter and power grounds. The base configuration for panel meters or counter consists of a main module (with computer and plug-in display boards), a power supply board, and a signal conditioner board. Optional plug-in-play boards include an isolated setpoint controller board, an isolated analog output board, and an isolated digital interface board. Modular design and a choice of plug-in options allow the Laureate to be customized for a broad range of applications from simple monitoring to control and computer interface. There can be up to five plug-in boards in a 1/8 DIN Laureate.

Connecting Laureate Panel Meters to a Local Area Network (LAN)

Up to 30 Laureate Panel Meters and/or LT Transmitters can be configured for RS485 and daisy-chained to an LT Transmitter using Laurel’s High Speed Ethernet-to-RS485 converter board for seamless LAN integration. Alternatively, Laurel LTE series Ethernet transmitters can connect directly to a LAN via an Ethernet cable. Setup for both configurations is streamlined using Laurel’s free Instrument Setup Software, which simplifies node discovery and transmitter configuration.

Flexible Communication Options for Panel Meters

Laureate Panel Meters can be equipped with Laurel communication boards to support various interfaces and protocols. These include serial interfaces with ASCII or Modbus RTU protocols, and Ethernet interfaces with web access, ASCII, or Modbus TCP/IP protocols, ensuring versatile connectivity for your commercial applications.

Understanding 1/8 DIN Panel Meters for Quadrature Encoder Input and Bidirectional Position or Rate

In industrial automation, robotics, and motion control systems where precise tracking of movement is essential for accuracy, safety, and efficiency, 1/8 DIN Panel Meters for Quadrature Encoder Input and Bidirectional Position or Rate are specialized instruments designed to deliver exact position and speed measurements. These Panel Meters interface directly with quadrature encoders to monitor linear or rotary motion in both directions, providing real-time data for closed-loop control. Their compact design, high resolution, and robust functionality make them indispensable in applications ranging from CNC machining to conveyor systems and robotic positioning. This section explores their functionality, features, technical advantages, and diverse applications across modern industrial and technical environments.

What are 1/8 DIN Panel Meters?

1/8 DIN Panel Meters are compact electronic instruments designed to process input signals and display measurement data in a clear digital format. The "1/8 DIN" designation refers to their standardized physical size, defined by the Deutsches Institut für Normung (DIN), a German standards organization. This size measures approximately 48 mm × 96 mm (1.89 inches × 3.78 inches) on the front panel, making them an excellent fit for control panels, instrumentation enclosures, and operator stations where space is limited but accurate data presentation is critical. The standardized dimensions ensure compatibility with existing panel cutouts, simplifying installation, upgrades, and replacements in both new and legacy systems.

These Panel Meters serve as versatile tools for monitoring a variety of parameters — including position, speed, rate, or direction from encoder signals. Their digital displays, typically featuring LED or LCD technology with adjustable brightness, provide high visibility and readability even in challenging lighting or from a distance. This makes the Panel Meters dependable choices for operators who need quick, accurate data interpretation to support informed decision-making and process control.

Quadrature Encoder Input Fundamentals

Quadrature encoders are sensors that generate two out-of-phase pulse trains (Channel A and Channel B) along with an optional index pulse (Channel Z). The 90-degree phase difference between A and B signals allows these Panel Meters to determine both the direction and magnitude of movement. This bidirectional capability is essential for applications involving reversible motion, such as robotic arms, linear actuators, or conveyor systems with forward and reverse operation. By counting pulses and analyzing phase relationships, these Panel Meters provide precise position feedback and rate calculation, supporting closed-loop control and high-accuracy positioning.

For example, in a CNC machine, the Panel Meters can track tool position with sub-micron resolution, while in a conveyor system they can monitor belt speed and direction to prevent jams or misalignment.

Bidirectional Position or Rate Measurement

The bidirectional position and rate measurement capabilities of these Panel Meters enable monitoring of movement in both forward and reverse directions. Position tracking accumulates encoder pulses to display absolute or relative location, while rate measurement calculates speed based on pulse frequency. This dual functionality is vital in applications where motion can change direction, such as reciprocating machinery, reversible motors, or positioning systems with homing routines. Advanced models include zero-channel index support for precise reference points and high-speed counting for dynamic environments.

In practice, bidirectional measurement ensures accurate control in systems like automated guided vehicles (AGVs) navigating complex paths or robotic arms performing pick-and-place operations with precise back-and-forth motion.

How Do 1/8 DIN Panel Meters for Quadrature Encoder Input Work?

The operation of the 1/8 DIN Panel Meters for Quadrature Encoder Input involves a carefully coordinated sequence of steps to deliver reliable and accurate measurements:

- Signal Acquisition

The Panel Meters receive quadrature signals (A, B, and optional Z channels) from the encoder via dedicated input terminals. These inputs support various signal types (TTL, open-collector, differential line driver) for compatibility with different encoder technologies. - High-Precision Pulse Processing

Internal high-speed counters and phase detection circuitry analyze the A/B signals to determine direction and count pulses. Advanced models apply x4 counting (detecting all four edges per cycle) for maximum resolution and noise rejection. - Position and Rate Calculation

The Panel Meters accumulate pulses for position tracking and calculate rate based on pulse frequency over time. Scaling factors convert raw counts into meaningful engineering units (millimeters, degrees, RPM). - Display & Output Capabilities

The final position or rate value is shown on a bright, high-contrast digital display. Many models also provide programmable outputs — such as relays, open-collector transistors, analog signals (4–20 mA or 0–10 V), or communication interfaces (RS-232, RS-485, Modbus RTU/TCP, Ethernet) — to trigger external actions, log data, or integrate with PLCs, SCADA systems, or remote monitoring platforms.

Key Features of the 1/8 DIN Panel Meters for Quadrature Encoder Input

The 1/8 DIN Panel Meters for Quadrature Encoder Input include a wide array of features that enhance their performance, usability, and integration capabilities:

- Exceptional Motion Accuracy

Support high-resolution counting (x1, x2, or x4 modes) with speeds up to 250 kHz or higher, ensuring precise position and rate measurements even in fast-moving systems. - Clear, High-Visibility Displays

Feature large, backlit LED or LCD displays with adjustable brightness and contrast, allowing easy reading in bright, dim, or variable lighting conditions commonly found in industrial and laboratory environments. - Compact 1/8 DIN Form Factor

Fit standard panel cutouts, making them ideal for crowded control panels or retrofits without requiring major modifications to existing equipment layouts. - Flexible Encoder Compatibility

Support a broad range of quadrature encoders (incremental, optical, magnetic) with differential or single-ended inputs and selectable voltage levels for versatile system integration. - Programmable Functions

Allow users to configure counting modes, scaling factors, preset values, alarm thresholds, relay actions, and output behaviors to match specific application requirements and operational workflows. - Robust Industrial Design

Built to withstand harsh environments, with high IP front-panel protection, wide operating temperature range, and resistance to vibration, shock, dust, and electrical noise.

Benefits of Using 1/8 DIN Panel Meters for Quadrature Encoder Input

Implementing 1/8 DIN Panel Meters for Quadrature Encoder Input delivers numerous advantages across industrial and research applications:

- Enhanced Motion Precision

Accurate bidirectional tracking reduces positioning errors, improves repeatability, and enhances overall system performance in automated processes. - Improved Accuracy & Repeatability

High-resolution measurements ensure consistent results in critical motion applications, reducing defects and improving quality control. - Cost-Effective Monitoring

The compact design and versatile features eliminate the need for multiple specialized counters or controllers, reducing hardware costs and panel space requirements. - User-Friendly Operation

Intuitive interfaces, programmable settings, and clear digital displays make the Panel Meters accessible to operators with varying levels of technical expertise. - Scalability & Future-Proofing

Easy integration with communication protocols and external systems supports expansion into larger automation networks or Industry 4.0 environments. - Reliability in Harsh Conditions

Rugged construction ensures long-term performance in industrial settings with temperature extremes, vibration, dust, or electrical noise.

Technical Specifications (Typical)

Specifications vary by model, but typical 1/8 DIN Panel Meters for Quadrature Encoder Input include:

- Input Compatibility: Quadrature A/B/Z channels, differential or single-ended, up to 250 kHz

- Counting Modes: x1, x2, x4 quadrature counting with direction detection

- Accuracy: ±1 count or better

- Display: 4–6 digit LED or LCD with adjustable brightness

- Power Supply: 12–24 V DC or 85–265 V AC universal

- Communication: RS-232, RS-485, Modbus RTU/TCP, Ethernet (optional)

- Outputs: Relays, analog (4–20 mA or 0–10 V), open-collector

- Environmental Rating: IP65 front panel, wide operating temperature

Applications of 1/8 DIN Panel Meters for Quadrature Encoder Input

The 1/8 DIN Panel Meters for Quadrature Encoder Input are used in numerous sectors where exact motion monitoring is critical:

- Industrial Automation & Robotics

Track position and rate in robotic arms, pick-and-place systems, and automated assembly lines to ensure precise, repeatable movements and reduce errors. - CNC Machining & Manufacturing

Provide position feedback for tool paths, spindle control, and axis positioning in CNC mills, lathes, and routers for high-accuracy machining. - Conveyor & Material Handling Systems

Monitor belt speed, length measurement, and direction in conveyors, sorters, and palletizers for synchronized material flow and inventory tracking. - Automated Guided Vehicles (AGVs) & Mobile Robotics

Track wheel position and velocity for navigation, path following, and collision avoidance in warehouse automation and logistics. - Printing & Packaging Machinery

Control web tension, registration, and cut-to-length operations with precise encoder feedback for consistent product quality. - Test & Measurement Laboratories

Provide accurate position and rate data in test rigs, dynamometers, and motion simulation equipment for R&D and validation.

Where Are 1/8 DIN Panel Meters for Quadrature Encoder Input and Bidirectional Position or Rate Used?

1/8 DIN Panel Meters for Quadrature Encoder Input and Bidirectional Position or Rate are deployed in environments where reliable motion tracking is essential for process control, safety, and quality. Their compact size, high accuracy, and robust features make them a cornerstone in industrial, manufacturing, and research settings. Below is a detailed exploration of the primary industries and use cases for these Panel Meters.

1. Industrial Automation

In industrial automation, these Panel Meters provide real-time position and rate data for coordinated machinery operations. They ensure optimal performance and reduce waste in automated systems like robotic assembly lines or chemical reactors.

2. Manufacturing

Manufacturing processes, including metalworking, plastics extrusion, and assembly, rely on precise motion control. These Panel Meters monitor encoder signals in CNC machines, extruders, or presses to maintain consistent product quality and prevent defects.

3. Laboratories

In research laboratories, these Panel Meters track motion in test rigs, environmental chambers, or simulation equipment. Their high accuracy ensures controlled conditions for experiments in materials science, physics, or engineering.

4. Robotics & Motion Control

Robotics systems use these Panel Meters to monitor joint positions and velocities in robotic arms or mobile robots. Accurate feedback ensures precise movements and safe operation in automated tasks.

5. Automotive Industry

In automotive manufacturing and testing, these Panel Meters monitor motion in assembly robots, test stands, or conveyor systems. They ensure optimal performance and compliance with standards in vehicle production.

6. Energy and Utilities

In energy systems, these Panel Meters track motion in turbines, pumps, or valves to ensure efficient operation and prevent failures in power generation or distribution.

7. Aerospace and Defense

In aerospace and defense, where precision and reliability are critical, these Panel Meters monitor motion in test equipment, simulators, or control systems. Their accurate readings ensure operational safety and performance in demanding conditions.

8. Food and Beverage Industry

In food processing, these Panel Meters ensure precise motion control in filling, packaging, or conveying systems, maintaining product quality and compliance with regulations.

Conclusion

1/8 DIN Panel Meters for Quadrature Encoder Input and Bidirectional Position or Rate measurement are versatile tools with applications spanning industrial automation, manufacturing, laboratories, robotics, automotive, energy, aerospace, and food and beverage industries. Their compact size, high accuracy, and robust features make them essential for precise motion monitoring and control. By providing reliable data, these Panel Meters ensure operational efficiency, safety, and quality across diverse sectors, solidifying their role in modern industrial and scientific applications.

Less Information...